Equipment for packing loose materials

Packing equipment

SITIX designs and produces systems for packing paper and plastic valve bags of 10 to 50 kg in different versions.

Our equipment is used for packing loose materials in chemical, construction, mining, food industry and agriculture.

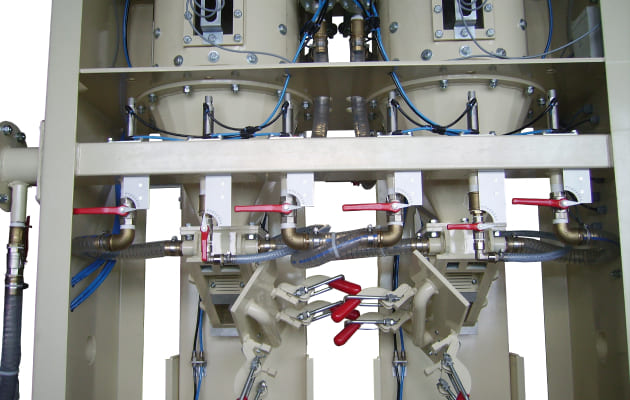

Packing machines for loose materials

We offer 2 types of packing machines for loose materials

Rotary packing machines BFM-R

- From 3 to 12 charging ports

- Capacity 1,050 – 4,200 bags/hour

- Packing in paper and polyethylene valve bags

- Optimal solution for packing different types of products

- Automatic bag size and type adjustment

Product feeding methods

For different types of materials we offer machines with turbine or air product feed system.

Turbine feed

BFM-Т

For packing products with grain size 0 – 4 mm

Turbine feed machines are intended for packing loose fine and powder products (cement, lime, slaked lime, gypsum, flour, pigments, etc.) in valve bags.

The finer the fraction and the more expressive are loose properties of the product, the more likely a turbine machine is suitable for filling.

Air feed

BFM-А

For packing products with grain size 2 – 8 mm

Air feed machines are intended for packing free flowing coarse materials (dry mortar mixes, soda, plaster, fish flour, bonding materials, foam plastic, food products, powders, etc.) in valve bags.

The coarser the fraction, the more likely an air machine is suitable for filling.

Auxiliary equipment and spare parts

We offer different types of auxiliary equipment and spare parts, including:

Our systems are suitable for such raw materials as

Cement

Plaster

Grains

Soda

Flour

Sugar

Fertilizers

Color pigments, etc

Frequently asked questions

Can your packing equipment be retrofitted with additional options?

Do you have any conveyors?

What is the period of waiting parts in case of possible breakdown?

-

Each project is developed individually

According to the client’s needs

-

We provide full-cycle services:

EngineeringDesigningProductionMountingPre-commissioning

German quality and reliability

High capacity

Gas and electric power saving up to 70%

Delivery and mounting within 1-6 months

Full technical support